Shopping cart

Longread | From linear to circular: transition tips for companies

Companies and governments are looking for ways to become more sustainable and reduce their impact on the environment. But how do you make the transition from linear to circular thinking and working? Based on our experiences with circular design, a sustainable production process and circular services, we share seven transition tips. There are also challenges. Dionne Ewen, Sustainability & ESG manager, explains what Ahrend encountered in practice.

In short: the linear economy

The linear economy stands for the traditional way of producing and consuming. Also called the 'take-make-waste' model:

- Take: raw materials are extracted from nature.

- Make: products are made from these raw materials.

- Waste: after use, products are often thrown away, incinerated or end up in landfills.

This model has functioned well for decades, but has major drawbacks. Raw materials are finite and waste and pollution are increasing. Moreover, linear thinking and working often leads to a waste of valuable materials and energy.

The circular economy

A circular economy is all about reusing and preserving raw materials and products for as long as possible. By keeping them in cycles, you preserve the value of materials and minimize waste. Important principles are:

- Restoring natural systems by using fewer materials and sustainable raw materials.

- Design products in such a way that they can be easily repaired or recycled.

- Keeping products and materials in use through reuse, repair, refurbishment and recycling.

Why take the step to circular now?

Climate change, depletion of raw materials and growing waste streams are forcing companies to take responsibility. At the same time, we see that consumers, investors and governments are placing increasingly higher demands on how companies deal with the climate. By investing in circularity now, you build sustainable growth and success. It's a strategic opportunity to drive innovation, inspire employees, and increase customer loyalty. Moreover, you contribute to a better environment and to society – a responsibility that counts more and more.

Seven transition tips

How do you invest in circularity? Introducing a new way of thinking and organizing takes time and attention. Our suggestions:

Start with awareness and vision

Start with the right mindset. Involve employees, management and stakeholders in developing a vision on circularity. Show why circular thinking and working is important – not only for the environment, but also for the company and society.

Analyze the current situation

Map out how your organization currently deals with raw materials, production, use and waste. Where are the greatest waste and environmental impact? Where are the opportunities for improvement?

Design or purchase: circular products and services

Encourage circular product design: modular, easy to repair, with sustainable and recyclable materials. Or purchase circular products and services. Also think of new business models such as 'product as a service', where customers rent or lease products instead of buying them.

Organise the chain in a circular way

Work together with suppliers, customers and partners who also strive for circularity and sustainability and make agreements among themselves. Focus on chain cooperation to take back, refurbish or recycle products or materials.

Measure, report, improve, and certify

Use concrete KPIs to monitor circular goals, such as material use, CO2 emissions, waste reduction and reuse. Set clear goals and evaluate regularly to improve circular performance. Talk to suppliers about the possibilities and developments and test them together.

Invest in knowledge and innovation

Immerse yourself in circular procurement and formulate challenging and achievable requirements for suppliers. Invest in R&D and foster a culture of innovation and experimentation within your company.

Secure circularity in your corporate culture

Make sure that circularity becomes part of daily practice and decision-making. Show what is already possible and what the company is already doing in the field of circularity. Involve employees, for example, ask them to think about circular actions. And communicate about it in the office (for example, provide information about the reuse of furniture).

Circular results and challenges

In everything Ahrend does, we strive to keep furniture in use for as long as possible. This provides examples of success but also challenges. Dionne Ewen, manager of Sustainability & ESG at Ahrend, tells us more about it.

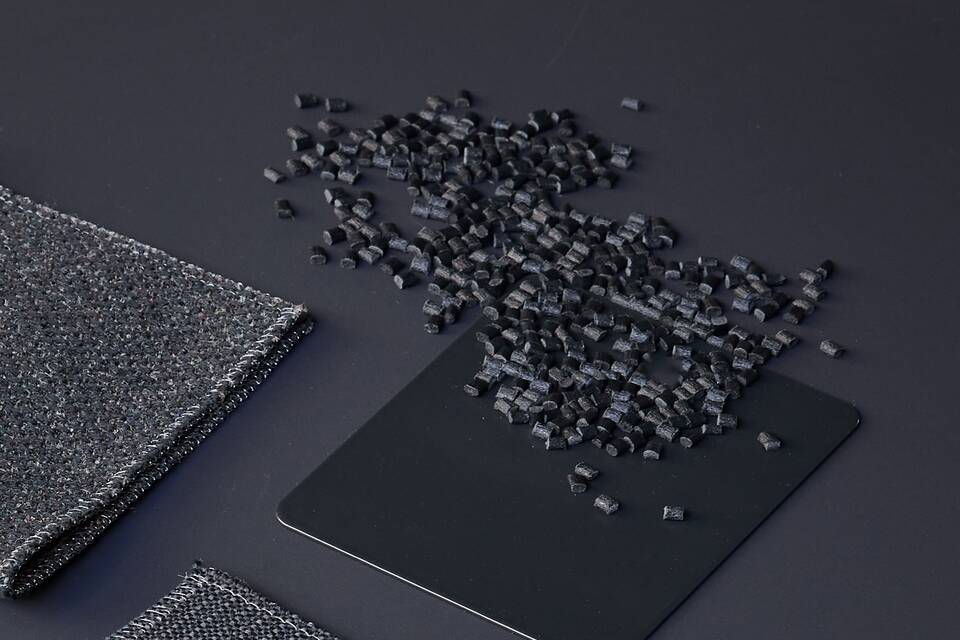

Recycled and sustainable materials

Dionne: 'We are integrating more and more recycled materials into our furniture, such as plastic, steel, aluminium and textiles. In this way, we reduce the environmental impact without compromising on comfort or design. One challenge is the availability of recycled materials. We also see that the quality of recycled plastics can vary greatly. Our focus is on what we can influence ourselves. For example, we are now developing closed cycles for our own production waste, from textiles and wood to plastics.'

Sustainable production and logistics

Dionne: 'The Ahrend production sites meet high environmental standards. Energy efficiency, waste reduction and responsible water use are key. To limit the ecological footprint, we encourage the use of sustainable packaging and optimal transport routes. We electrify our trucks in the Benelux. The challenge here: the investment costs for new trucks are high and unfortunately they cannot be charged everywhere."

The Circular Hub

In Ahrend's Circular Hub in Veghel, used furniture is completely disassembled, repaired, cleaned and, where necessary, renewed. Products are given a second life, including warranty and certification. Dionne: 'At the start, our big question was: is there business for this? And how do we make this profitable? A lot of certain pieces of furniture are returned, others only a few. Also challenging was refurbishing furniture from other suppliers. In order to discover, learn and gain speed, we have deliberately separated the Circular Hub from our production locations completely. So that you are not limited by the ongoing processes there. Where we used to revitalize about 5,000 products per year, there were already 70,000 in the first year of the Circular Hub. We are now scaling up further.'

Value Hill model

Ahrend works according to the Value Hill model, with a focus on extending the lifespan of products through maintenance, refurbishing and reuse. Raw materials are used efficiently and CO2 emissions are kept as low as possible. At the end of their use, furniture serves as a raw material for new products. Dionne: 'The Value Hill model helps us to explain circularity properly to customers, because it is more than recycling. Circular working means a change: you organize your production differently, new services are added, Sales has different conversations. Your entire business operations will change.'

Furniture as a Service (FaaS)

Dionne: 'We offer customers the opportunity to lease furniture instead of buying it. With the FaaS model, furniture remains the property of Ahrend. After use, we take them back and ensure maintenance and reuse. This makes it easier for customers to set up circularly. The challenge for us is that we work in a procurement market, in which it is often about buying instead of leasing. FaaS also requires a certain mindset from customers.'

Ahrend 230 office chair

Fifteen years ago, the Ahrend 230 office chair was the first cradle-to-cradle certified product and we are still proud of that. The chair is modular and we produce it with sustainable materials. We often receive these office chairs back in the Circular Hub; Due to the good design, they are easy to revitalize.

What are the next steps?

Ahrend is now rolling out the circular proposition internationally. In addition, we want to measure the environmental impact more often, so that we can communicate more transparently about circularity and its benefits. Dionne advises: 'Every company can contribute to a circular future. Start today with small changes, dare to experiment and make circularity part of your strategy.'