Royal Ahrend calls for acceleration of circular economy

May 13, 2025

"From small-scale circular initiatives to a large-scale industrial model."

The urgency for a circular economy has never been greater. Not only because of climate change and the need for a healthy living environment, but also from an economic perspective. With raw materials becoming increasingly scarce, it is essential to use products, materials and resources for as long as possible to maintain a strong economy. By harvesting from what already exists, we reduce our dependence on other countries for raw materials. Circularity is a serious strategic asset for Europe in the current geopolitical struggle. It is no coincidence that Mario Draghi highlights it as a spearhead in his report on European competitiveness. Yet progress remains slow.

Time to take action now

After more than ten years of government efforts focusing circular policies and procurement in select industries, the first steps have been taken. But this is just the beginning. It is time for the Dutch manufacturing sector—world-renowned for its innovation and quality—to push forward. The Integrated Circular Economy Report 2025 shows that circular initiatives still lack sufficient scale. The markets for circular products remain limited. Labour-intensive processes involved in refurbishing goods are inefficient, hampering consistent quality and attractive pricing of circular products. Moreover, the tight labour market means there are not enough skilled workers available to refurbish at scale across the manufacturing sector. Staff shortages are thus slowing the transition to a circular economy.

Industrialising circularity

The key to acceleration lies in automating and optimising circular production processes: by refurbishing smarter and more efficiently, we can truly make an impact. This increases scalability and enhances quality. By returning products to manufacturers’ factories and refurbishing them industrially on a large scale, producers can guarantee the same quality as new. The same European quality, safety and labour standards apply as with new products.

Digitalisation and robotics can help optimise circular production processes and address labour shortages in the Netherlands. Efficiency enables circular producers to compete with linear producers. Ultimately, the circular revolution provides us with competitive resilience. By making maximum efficient use of two scarce resources—raw materials and labour—The Netherlands and Europe become less dependent on raw material extraction. Meanwhile, scarce labour remains available for sectors where it is most urgently needed, such as the energy transition, construction, and healthcare.

Concrete steps

Ahrend and Gispen are already taking concrete steps towards industrialising circularity. At our production site in Sint-Oedenrode, refurbishment has been integrated into the regular production process. Here, used furniture is repaired and reused directly alongside new products. The boundary between ‘new’ and ‘used’ blurs: a ‘new’ chair may contain refurbished parts—and vice versa. This is how we make circularity scalable and future-proof.

Towards Circular Economy 2.0

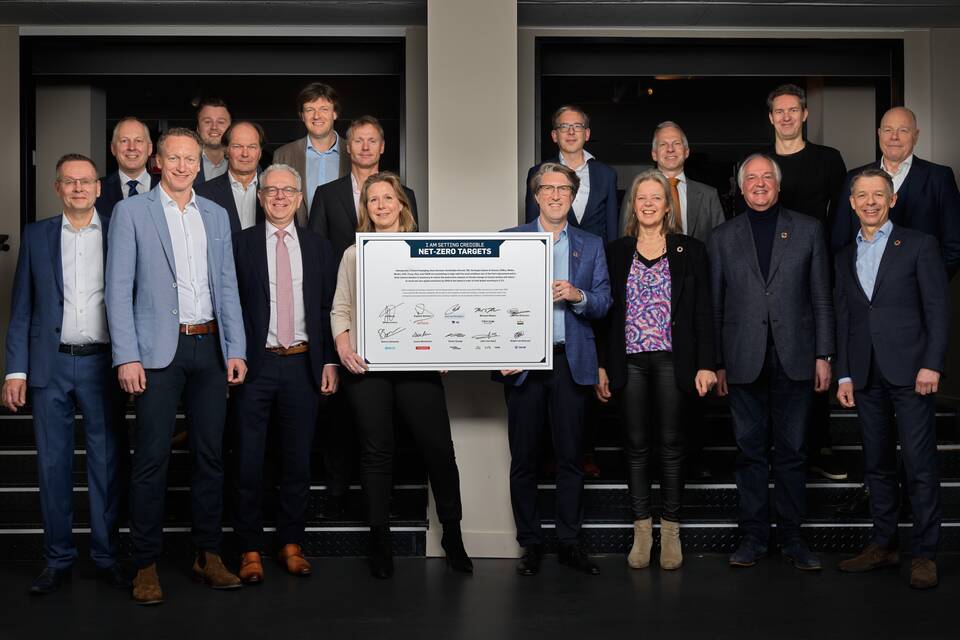

Strong progress has been made in recent years towards a circular economy. As a company, we have invested in circular design, modular product development, and advanced refurbishment and recycling processes. But circularity cannot be achieved alone—it is a collective effort. Together with customers, suppliers, competitors, and government. Only through collaboration can we make the circular economy the new norm. That is why we invite government, industry and knowledge institutions to join us in taking the next step.

By working even more integrally together, we will accelerate circularity. We will transform it from a niche market into a professional industrial standard—resulting in full-time jobs and high-quality end products.